Saturday, March 14, 2009

Casey Luke

I was browsing on eBay when I came across a steal! A gentleman was selling some plywood that he had leftover from building his own boat. He dropped the price easily 65% from retail. Unfortunately it was in California, so I listed my shipment on an online auction and was able to get the eleven pieces of wood from California to Texas for only $200. After a few more negotiations of price I made the purchase. To top it off my father paid for the delivery! He offered to pay for the whole thing but I felt bad doing that. I have wasted enough of his money over the years.

The guy who delivered the wood primarily ships motorcycles, however on this delivery he had a cat in the cab for some woman in Florida, my plywood, and bunch of junk for some person in Austin and a ¼ scale Ferrari – the real deal! This cool little car was actually made by Ferrari down to the last bolt. The only part that was not Ferrari was the engine –it was a Ducati motorcycle engine that would allow this tiny vehicle to travel up to 70 MPH. The buyer paid over $40,000 for it. You gotta really like go carts to pay $40 G for one.

+copy.JPG)

The wood needed to build a boat like the one I'm working on is very specific. The lumber I purchased originally came all the way from France. It is constructed with a special marine glue and void less laminates and must conform to a specific standard – the British Standard 1088. There can be no compromise when it comes to the wood. Bad wood will rot and fall apart.

My friend Javier helped me move the wood into the house. I originally planned to cut the wood with a circular saw and purchased a 4 x 8 sheet of insulation on which to lay the wood while cutting.

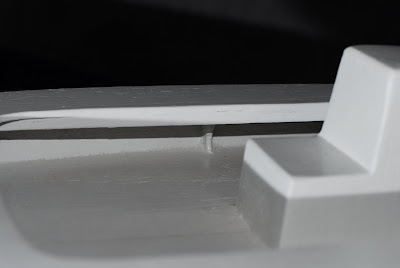

However, my father came to town and after lofting out the dimensions, we were able to knock out the cuts on the bandsaw in no time. This allowed for a very true cut on the stringers. We then smoothed out any wobble in our cuts with a low level plane.

As for the bulkheads, we used a new Bosch 1590 EVSK jig saw equipped with a fine tooth wood cutting blade. A large drywall T-square purchased at Lowes did just the trick for achieving near perfect cuts. If you clamp the T-square toward the inside of the bulkhead then any missed cuts always happen away from your work. If you make a mistake you simply back up and start again adjacent to the T-square, thus cutting the mistake right off the bulkhead.

To cut the slots needed to join the bulkheads and the stringers, I simply set up the T-square for the first cut and then placed another piece along the T-square, being the exact width as the slot, minus the saw blade kerf thickness.

Once all of the bulkheads and stringers were cut, I set the cut wood up in my den. In this picture you are able to see the size in comparison to Summer, my wife, hiding behind one of the bulkheads in the picture. Everything came out very well for this first group of cuts. I am very pleased.

+copy.JPG)